Description

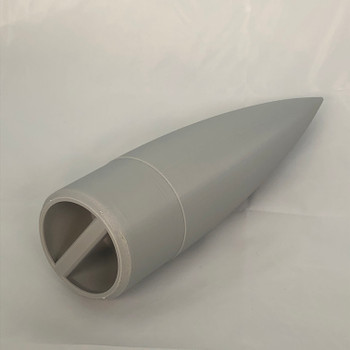

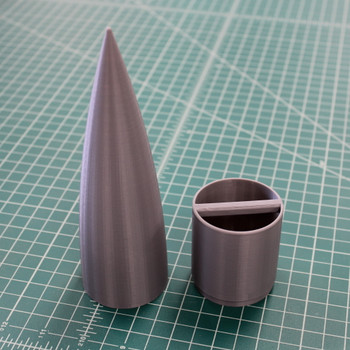

Number 9 lead shot helps maintain stability when upgrading motor size on short, stubby rockets. Use simulation software to calculate the amount of nose weight you'll need for your particular rocket, and choose the amount of shot you need, in grams from this list above. To add nose weight to your rocket, use sandpaper or a metal rod to rough up the surface of the inside of the nose cone where you add the nose weight. Invert the nose cone, and mix up a batch of 30 minute epoxy, making note of the weight of the epoxy. Pour half the epoxy into the nose cone. Gradually pour in the lead shot, letting it sink into the epoxy. Keep adding lead shot until you've added enough mass of epoxy and lead shot to equal the nose weight you need for stability. Allow the lead shot to fully sink into the epoxy. If lead shot remains exposed on top of the epoxy, add a layer of epoxy to fully encase the lead.

Warning: Lead has been shown to cause developmental delays in children, and should be handled with care. Wear gloves and a respirator when working with lead, and be sure to fully encase lead shot in epoxy in your rocket. Avoid ingestion or inhalation of lead or lead dust and clean work surfaces and tools after working with lead shot.